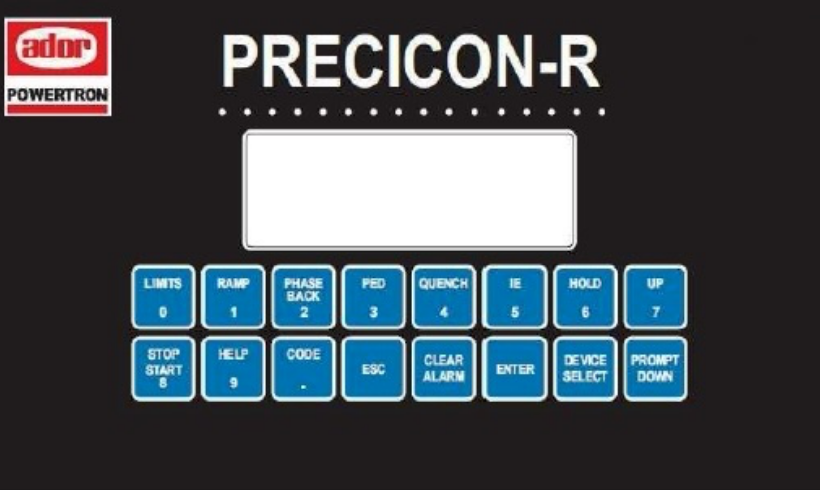

NOT JUST A TR CONTROLLER, BUT AN ESP CONTROLLER!

Precicon-R

Features

Specifications

- In-built Auto-optimization Software to control back corona by automatic charging ratio as well as current limit optimization.

- In-built Power Down / Control Rapping software to reduce back corona & achieve cleaner collecting Plates.

- Integration of Voltage / time curve by Active corona time determination.

- In-built rapping programmer with multiple control & operation options with Real time synchronization

- Inbuilt Opacity Optimization software.

- In-built Redundancy: Automatic changeover to manual control with full spark, arc and over current facilities should main processor fail.

- High Noise Immunity in entire control

- Arc Detection & quenching: Controller has the ability to separately detect spark & Arc.

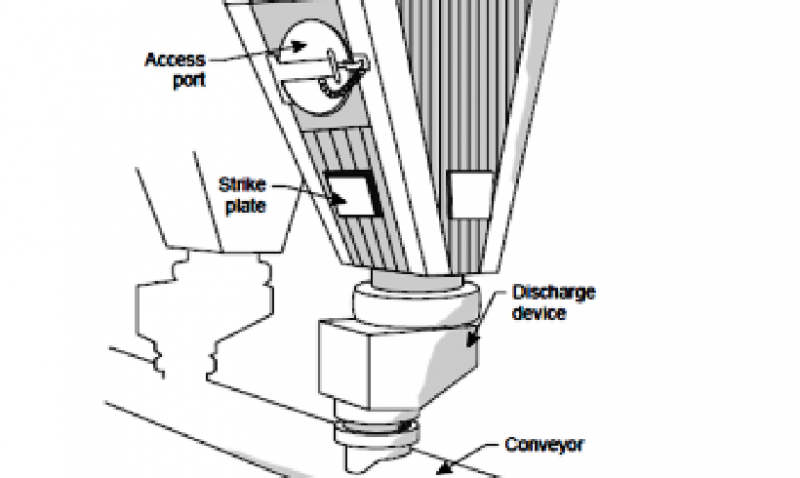

- Integrated Controller, which can control TR, rapper, heater etc. Thus separate rapper controller & heater controller is not required.

- Ability to regulate / adjust Current Limit, Charging Ratio, Spark Rate .

- Permits the control to choose the operating parameters based on an entered spark rate.

- Ability for high-speed reference data acquisition for comparison, analysis and adjustment based on voltage and current feedback.

- Ability to optimize ESP performance without the feedback from Opacity monitor.

- Ability to reach back to highest possible KV level (just below the spark level immediately after spark in order to reduce the idle field time to optimize ESP collection efficiency.

- Single point Operation, Control & Monitoring of all fields through a computer over Ethernet communication network without the necessity to reach physically individual TR panel.

- Inbuilt facility for On-line Voltage-Current characteristic.

- Display of On-line true value of kV, mA and all parameters in engineering units.

- Advanced feature for detection and quenching of Spark.

- Display of total spark accumulated.

- Display of all alarm in one window with clear message in language for ease of troubleshooting.

- Built in facility for measurement and display of Power consumption for individual field as well for total ESP.

- Rapping programmer is an integrated part of the controller without the necessity of separate controller with facility to program periodical, continuous rapping for better electrode cleaning. This operates on real time clock basis with 24 hours adjustment option with the facility to achieve the advantage of Power Control Rapping.

- Also compatible with tumbling hammer rapper.

- Password protection facility to stop unauthorized handling.

- It has inbuilt output for remote display of KV and mA.

- The controllers have analogue input facility to interface with opacity monitor.

- Auto regulation of power input for continuous emission improvement is independent of opacity monitor feedback.

- Displays semi pulse current limit

- Spark rate can maintained suitably even when CR differs due to gas flow, gas temperature and dust composition.

- Has Back Corona detection alarm and Management failure alarm.

- It has a non-volatile memory and report storage capability for a period of 1 year.

- Built in software to maintain optimum level of Power Input constantly without human interference

- Ability for auto control of back corona by reducing average current from TR.

Temperature Range |

0°C to 60°C |

Humidity Range |

0% to100% non-condensing |

Communications |

Optically Isolated |

Communications Port |

CAN BUS |

Alarm Inputs |

Optically isolated |

Memory Type |

Flash |

Control Voltage Range |

85 to 132 V AC |

SCR Gate Circuits |

Optically and transformer isolated |

Surge protected |

Up to 5,000 volts |

Component enclosure |

Baked Enamel; Powder Coated Aluminum |