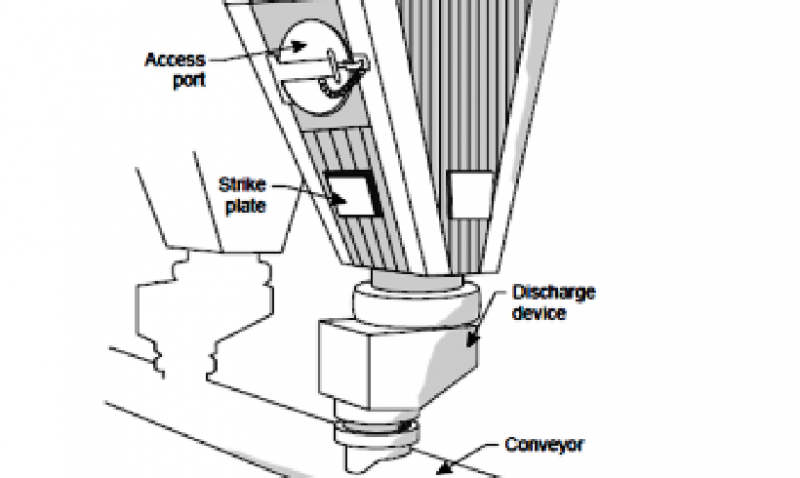

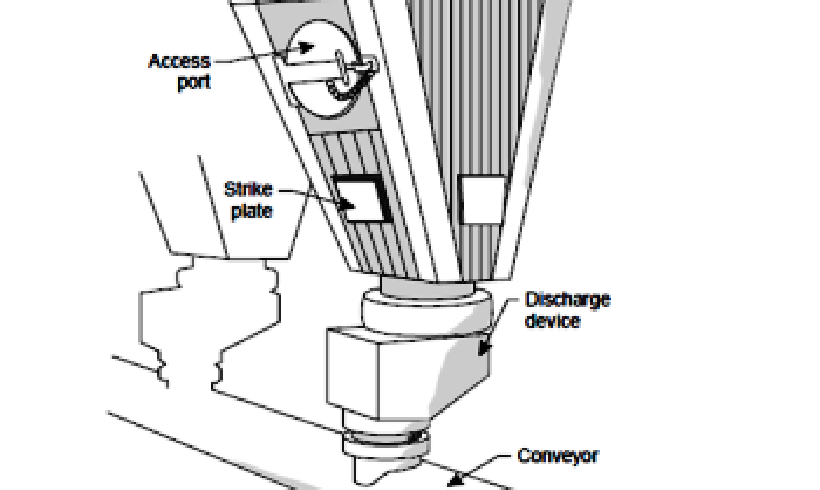

When the electrodes are rapped, the dust falls into hoppers and is stored temporarily before it is disposed in a landfill or reused in the process.

Hopper heaters and other accessories

When the electrodes are rapped, the dust falls into hoppers and is stored temporarily

before it is disposed in a landfill or reused in the process. Dust should be removed as soon as possible to avoid packing, which would make removal very difficult. Hoppers are usually designed with a 50 to 70° (60° is common) slope to allow dust to flow freely from the

top of the hopper to the bottom discharge opening.

PURGE AIR BLOWER

Purge air blower ensures positive air pressure inside the pent house with

respect to ESP casing. The air flows along the inside surface of the support

insulators thereby keeping the insulators clean. All the TR sets are wired for

tripping in case the Purge Air Blower Trips.

PURGE AIR HEATER

Thermostat is provided in the purge air heater to protect the purge

air heating elements from over temperature. Unless purge air heater is ON, purge air blower should not start.

HOPPER LEVEL INDICATOR:

Level switches (LSH1 to LSH3) are provided in each

hopper. The level switch operates when ash level inside the hopper rises & touches the level switch probe. The level switch gives signal to the audio visual alarm provided in the Aux. control panel to indicate high ash level in the hopper & trips the TR set. Even after tripping the TR set, the dust will continue to build up in hopper. Aux. contact of High hopper level relay will provided in the Aux. control panel. If the high level alarm is

persisting, it is recommended to stop the boiler after one hour time delay. This prevents ash-building up in the hoppers which ultimately shorts the discharge & collecting plates.

Hopper Heaters for ESP

Hopper Heating Elements:

Moisture content and low temperature of fly ash while passing through ESP will affect performance of the system, due to the chocking and accumulation of built-up ash inside the Hopper. Heaters are provided on all sides to maintain temperature inside hopper for effective ash disposal system.

Heater for Support Insulator:

To maintain temperature of passing Air through insulator housing.

– Rating : 500W – 1.1 KW.

– Diameter of Coil : 8 mm.

Material of Construction:

– Sheath Material – Heat Resisting Chromium

– Alloy Steel Ferrous Parts – Galvanised

– Brass parts – Nickel Plated

– Terminal Box – Cast Aluminium