Typically used in conjunction with rigid frame and Spiral discharge electrodes, are highly efficient , when employed in a moving gas stream.

Tumbling hammer

Description

Specifications

Hammers are connected to a rotating shaft. As they revolve, the hammers collide with a beam, causing a vibratory shock to dislodge caked-on dust. The hammer’s weight and mounting arm length control the intensity of the rapping. Adjusting the speed of the rotating shaft alters the frequency of rapping.

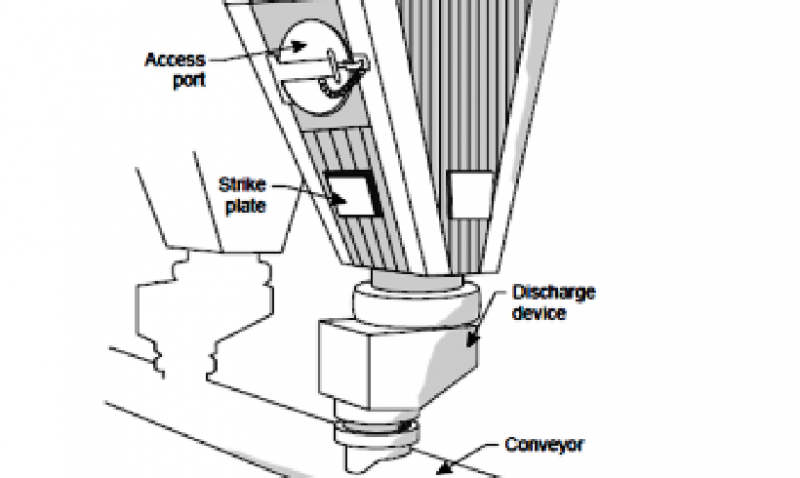

MAJOR SYSTEM COMPONENTS FOR TUMBLING HAMMER

– HAMMER FOR C.E & D.E RAPPING .

– BEARING FOR C.E & D.E RAPPING

Tumbling Hammer Based

– Rapper Shaft.

– C.I Bearing.

– Thrust Bearing.

– Drive Bearing for CERM.

– Hammer.

– Inner Arm & Outer Arm.

– Geared Motor along with Gear box.